Identifying the electrostatic characteristics of a material is an important step when evaluating the hazards associated with a process, especially for those that handle materials that exhibit low ignition energies.Charge separation and accumulation are inherent problems resulting from industrial operations  that handle powders of low conductivity. This charge separation and accumulation is a product of the friction and impact between particles that occurs during the movement of granular material during a variety of typical process operations.To identify potential static electrical hazards of a material, it is important to evaluate the level of charge separation and accumulation that occurs during transport, the resistivity of the material and how quickly any accumulated charge can be dissipated.

that handle powders of low conductivity. This charge separation and accumulation is a product of the friction and impact between particles that occurs during the movement of granular material during a variety of typical process operations.To identify potential static electrical hazards of a material, it is important to evaluate the level of charge separation and accumulation that occurs during transport, the resistivity of the material and how quickly any accumulated charge can be dissipated.

Materials we refer to here include all types of flammable hazards including combustible dust/dust hazards, flammable liquid, flammable gas and flammable vapors. The prevention of dust explosions and other fire hazards are are the basis of comprehensive process safety management programs. Necessary combustible dust testing, liquid flammability testing and other flammability hazard testing are defined by the unique setting of each work environment.

Streaming current is defined as the current generated from the flow of charged materials. The level of streaming current generated depends upon the static electricity characteristics of the material and the nature of the process. Unfortunately, there is no relationship between the streaming current in powders and that of liquids (1). In these instances, experimental determinations must be made to identify ignition hazards that may result from charge accumulation during process operations. From these types of experiments the charge density of a material can be calculated which can then be compared to typical charge densities associated with process operations. A list of charge density ranges observed during various operations that process non-conductive powders are shown below.

1 R.A. Mancini, “The Use (and Misuse) of Bonding for Control of Static Ignition Hazards, “Plant/Operations Progress (Jan.1998) 7(1): 24.

To identify the streaming current and charge accumulation of a material, Fauske & Associates (FAI) provides a Powder Chargeability test. The test procedure involves pouring a known amount of material down an inclined section of pipe. The powder then exits the pipe, falling into a Faraday cup. During the test, the charge that accumulates in the Faraday cup is measured using a coulomb meter and the flow rate of the powder is recorded on a mass per time basis. This data can then be used to approximate the charge density of a material.

To further classify the powder, it is necessary to evaluate the resistivity of the material. This is done per ASTM D257. The resistivity of a powder is governed by the particle size, level of surface contamination and packing density of the material and often is quite different than the resistivity of the material in its pure solid form. Powders with high resistivities typically lose their charge very slowly, even when the process equipment is properly grounded. In some instances, this can translate to poor heat dissipation and can lead to potential fires (2). More importantly, improper handling of materials with both high and low resistivity can create hazardous scenarios. Insufficient grounding and bonding of process equipment can lead to high levels of charge accumulation. At some point, a threshold is reached and charge breakdown occurs resulting in an static electricity discharge that could potentially ignite nearby flammable vapors or combustible dusts.

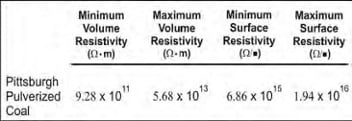

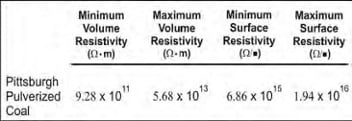

At FAI, we follow ASTM D257 to evaluate the volume and surface resistivity of a material. The volume resistivity can be determined by measuring the electrical resistance between opposite faces of a volume of powder. The volume resistivity of the material, commonly expressed in ohm-meter, can then be used to classify the material as either a conductive, dissipative or insulative. Likewise, the surface resistivity can be characterized by slightly modifying the test procedure. The units for surface resistivity are ohms per square. The square refers to any square geometry of a material, whether it be a square meter, square foot or square centimeter. The ranges used to characterize a material based on these parameters are shown below.

Results from a resistivity test conducted on a Pittsburgh pulverized coal sample using this method are shown below.

Another important electrostatic characteristic is the charge relaxation time of powders. This property varies greatly amongst different materials and is hard to estimate even if the dielectric constant of the material is approximated because it does not follow the hyperbolic trend found in liquids. The proper method to evaluate the charge decay time of a specific powder is to directly measure it. Once an understanding of the time required for a charge to relax for a given powder is gained, process parameters such as flowrate or hold up time, can be adjusted and proper grounding and bonding of equipment can be implemented to reduce the amount of charge that accumulates during a given process.

At FAI, a JCI 155 Charge Decay Test Unit is used to measure the charge decay of powders. This piece of equipment is programmed to apply a 10 kilovolt corona charge to a powder sample which is virtually immediately exposed to a field meter after charging occurs. The field meter measures the initial charge the material received and the time it takes to relax. The decay time is reported for both the time it takes for the charge on the sample to relax to 37.9% (1/e) of its initial charge and the time it takes for the charge to reach 10% of its initial value. Below is a plot and summary of the data collected from a charge decay test conducted on a sample of Pittsburgh pulverized coal.

From the tests conducted on Pittsburgh pulverized coal, it can be seen that the material is very resistive in powder form. Processing this material will likely result in charge accumulation and could reach conditions that result in a hazardous static electricity discharge. However, by utilizing this data, it is possible to minimize this risk by implementing proper grounding and bonding of process equipment. The data also provides clues on how to adjust process parameters to reduce charge build up and ultimately help work towards creating a safe work environment.

Gaining an understanding of the electrostatic characteristics of a particular material can greatly assist in the assessment and mitigation of fire and explosion hazards in the process environment. For additional information on assessing electrostatic hazards, please contact FAI at dust@fauske.com or 630-323-8750.

References

Pratt, Thomas H. Electrostatic Ignitions of Fires and Explosions. New York : American Institute of Chemical Engineers, 2000.

Britton, Laurence G. Avoiding Static Ignition Hazards in Chemical Operations

Very often, when performing dust and explosibility testing quotes for customers, we are asked what exactly a Go/No-Go test is? While we offer a list of testing services to determine the deflagration hazards of dust samples per ASTM (American Society of Testing and Materials), OSHA (Occupational Health & Safety Administration, NFPA (National Fire Protection Agency) and UN (United Nations), knowing what this basic test is can go a long way for tackling your safety needs.

Very often, when performing dust and explosibility testing quotes for customers, we are asked what exactly a Go/No-Go test is? While we offer a list of testing services to determine the deflagration hazards of dust samples per ASTM (American Society of Testing and Materials), OSHA (Occupational Health & Safety Administration, NFPA (National Fire Protection Agency) and UN (United Nations), knowing what this basic test is can go a long way for tackling your safety needs. that handle powders of low conductivity. This charge separation and accumulation is a product of the friction and impact between particles that occurs during the movement of granular material during a variety of typical process operations.To identify potential static electrical hazards of a material, it is important to evaluate the level of charge separation and accumulation that occurs during transport, the resistivity of the material and how quickly any accumulated charge can be dissipated.

that handle powders of low conductivity. This charge separation and accumulation is a product of the friction and impact between particles that occurs during the movement of granular material during a variety of typical process operations.To identify potential static electrical hazards of a material, it is important to evaluate the level of charge separation and accumulation that occurs during transport, the resistivity of the material and how quickly any accumulated charge can be dissipated.