By: Mark Yukich, S&B Development, Fauske & Associates, LLC (FAI)

By now, most of us have heard that NFPA 652 has been released, so what does that mean? The highlights are that you will be required to evaluate combustible dust hazards that may exist at your facilities by conducting a Dust Hazard Analysis or DHA within 3 years of NFPA 652’s release date of October 2015. That means that NFPA 652 asks operators of facilities to identify combustion hazards involving dusts and powders and then implement needed protective measures and safeguards by October 2018. Please note that dusts, powders, flock, flyings and fibers are categorized into one general group as “dust.” According to Susan Bershad, the NFPA staff liaison for the combustible dust technical committee, there are the following 3 fundamental principles in the standard: containing the fuel, controlling the ignition sources and limiting the spread of any combustion event. Those elements can be found by conducting a DHA, which will need to be revalidated at least every 5 years.

NFPA 652’s release date of October 2015. That means that NFPA 652 asks operators of facilities to identify combustion hazards involving dusts and powders and then implement needed protective measures and safeguards by October 2018. Please note that dusts, powders, flock, flyings and fibers are categorized into one general group as “dust.” According to Susan Bershad, the NFPA staff liaison for the combustible dust technical committee, there are the following 3 fundamental principles in the standard: containing the fuel, controlling the ignition sources and limiting the spread of any combustion event. Those elements can be found by conducting a DHA, which will need to be revalidated at least every 5 years.

In NFPA 652, the term “Dust Hazard Analysis” or DHA is introduced. This is designed to differentiate from the more complex Process Hazard Analysis or PHA required by the OSHA Process Safety Management (PSM) program for the chemical process industry. Many print and electronic publications are spreading Fear, Uncertainty and Doubt (FUD) by mixing up the requirements for an OSHA PSM PHA with the less arduous DHA approach mentioned in NFPA 652. Industrial and academic experts in the area of combustible dust, fire and explosion safety guided the formation of 652. Its purpose is to give personnel a single source for information on the fundamentals of safe handling combustible dust and powders in and industrial setting. The standard also directs users to commodity specific standards such as the following which offer material and production specific guidance:

• NFPA 61 – Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities

• NFPA 484 – Standard Combustible Metals

• NFPA 654 – Prevention of Fire and Dust Explosions from the Manufacturing, Processing and Handling of Combustible Particulate Solids

• NFPA 664 – Wood Processing and Woodworking Facilities

The reason for an implementation deadline for the DHA is to encourage that proactive actions are taken in completing the assessment. According to Guy Colonna, NFPA division manager of industrial and chemical engineering, “The concern is if there’s no timetable, it would never get done.” Colonna went on to say, “The committee is not proposing a shutdown and redesign of every industrial facility where solids are handling and dust could be present. They’re starting with saying: ‘Do the DHA. See what it tells you.’”

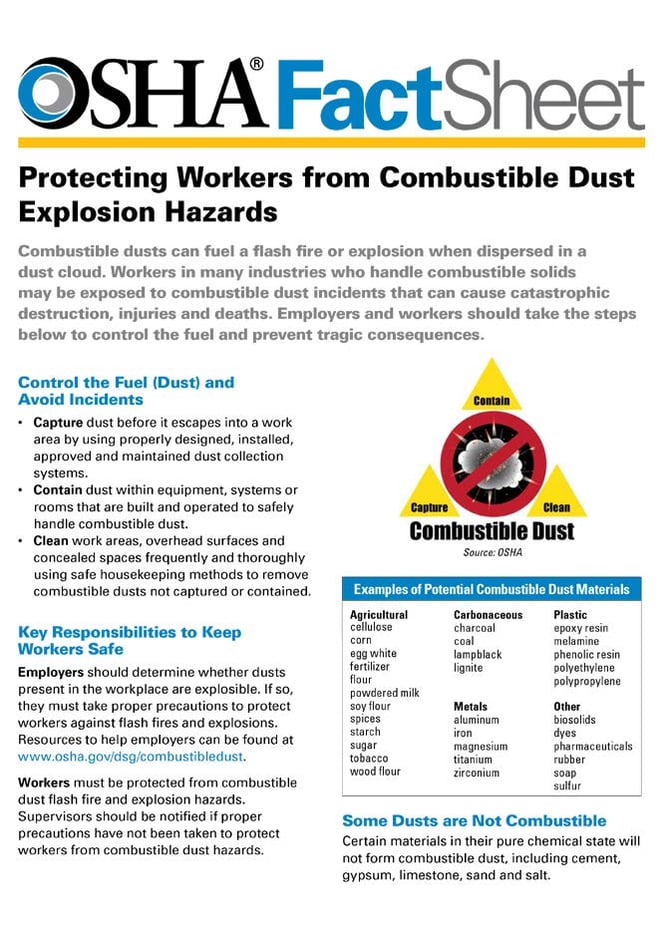

Chemical Safety Board (CSB) Chairman, Vanessa Sutherland said, “Their internal practices are focused on minimizing the amount of accumulated dust, making sure it’s less of a hazard, and also workers are kept up to date on new practices and consensus standards through NFPA.” According to Sutherland, employers can take three actions to protect against explosible dust hazards:

• Review CSB Materials, including a safety video and investigation reports

• Review and adopt NFPA standards

• Pay greater attention to worker training and facility housekeeping

OSHA offers other combustible dust and ignition source control recommendations, as well as guidance on injury and damage control methods. The following are some key recommendations, presented in no particular order:

- Enforce a program that includes dust inspections, testing, housekeeping and control

- Use appropriate dust collection systems and filters

- Limit escape of dust from equipment or ventilation systems

- Use surfaces that limit dust accumulation and ease cleaning

- Regularly check for dust residue in all areas, including hidden locations

- Clean without creating dust clouds around ignition sources

- Operate vacuum cleaners certified for dust collection

- Use appropriate electrical equipment

- Keep heated surfaces and systems away from dust

- Create an emergency plan

The recently published OSHA fact sheet is provided here your reference:

For more information, please contact Mark Yukich at yuckich@fauske.com, 630-887-5788

#process hazards #hazardous dust